Machinery Space Systems

On vessels of almost every size, the machinery space is often the greatest source of noise. To reduce airborne sound from this space, knowledgeable experts will coordinate an insulation solution.

Barrier composite insulation on the overhead and bulkheads is usually your first step. Alternating layers of mass-loaded vinyl and acoustic foam create a sound-reducing formula. The foam absorbs noise while the mass-loaded layer reflects noise back into the engine room, protecting accommodation areas. Soundown’s IVF (insulated vinyl/foam) composite sheets are highly effective aboard vessels up to 65′ and are easy to install in new builds or during refit.

engine room, protecting accommodation areas. Soundown’s IVF (insulated vinyl/foam) composite sheets are highly effective aboard vessels up to 65′ and are easy to install in new builds or during refit.

Soundown IVF and other insulation products are available in a range of thickness and barrier surface densities. As thickness and weight increase, so does the ability of the materials to absorb and block noise. Installing the greatest thickness possible for the given space will provide the best results.

Best bet: 2” 2lb for diesel engines, 2” 1lb for gas engines. Or, for very best results, give a Soundown expert the specifications for all of the equipment in your machinery space.

For hull sides or fuel tanks outboard of the engines, the next solution we recommend is Soundown’s IAF acoustic foams. IAF does not feature a barrier – the foam absorbs noise in the machinery space, resulting in less noise in the accommodations. The foam also is effective at reducing airborne noise that often escapes through the ventilation system into the rest of the vessel.

Best bet: 1”

For vessels over 65′ and commercial vessels, the use of a non-combustible acoustic insulation is suggested and often required by the Coast Guard or your classification society. Soundown offers fiberglass and mineral materials that can be supplied as a ready-made composite or assembled to fit the recommended build schedule for the vessel.

The detail (1) below shows Soundown Lead Coast Guard Board that is typical of the insulation for a USCG Sub Chapter T vessel, such as a dinner cruiser or whale watch boat, that can require insulation compliant with USCG 164.009.

Larger yachts and offshore commercial vessels require structural fire protection (SFP) that meets requirements for A30 or A60. Soundown offers a number of options that provide acoustic performance while meeting regulatory requirements for fire safety. Options include mineral wool, Firemaster, and Promaguard. These options provide the required performance at different weights and thickness properties that can be chosen based on vessel requirements.

Larger yachts and offshore commercial vessels require structural fire protection (SFP) that meets requirements for A30 or A60. Soundown offers a number of options that provide acoustic performance while meeting regulatory requirements for fire safety. Options include mineral wool, Firemaster, and Promaguard. These options provide the required performance at different weights and thickness properties that can be chosen based on vessel requirements.

Mineral wool is the most commonly used material and is an excellent choice where weight and space are not a concern. Typical A60 performance requires 3″ of 8lb/ft3 material on flat plate and 1.5″ over the stiffeners.

Firemaster is ceramic blanket material that is easy to handle and offers weight and space savings over mineral wool. A typical A60 installation requires 1.5″ on the flat plate and a 1″ wrap for beams and stiffeners at 6lb/ft3.

Promoguard, a micro-porous stitched mat, offers the thinnest solution for A60-rated surfaces. Two layers of 10mm Promoguard provides A60 insulation on aluminum decks or bulkheads.

When choosing structural fire protection materials, it is important to note that material certificates are based on the substrate and type of surface to which they are applied. The test for decks is different than for bulkheads because the bulkheads need to retain their load-bearing capacity. For this reason, the insulation thickness required on the overhead is most often less than is required for a bulkhead.

It is also important to review the tested substrate when selecting structural fire protection materials. If the insulation is tested on steel, that will be stated on the material certificate and means it is not applicable on aluminum or FRP unless additional certificates exist that state otherwise.

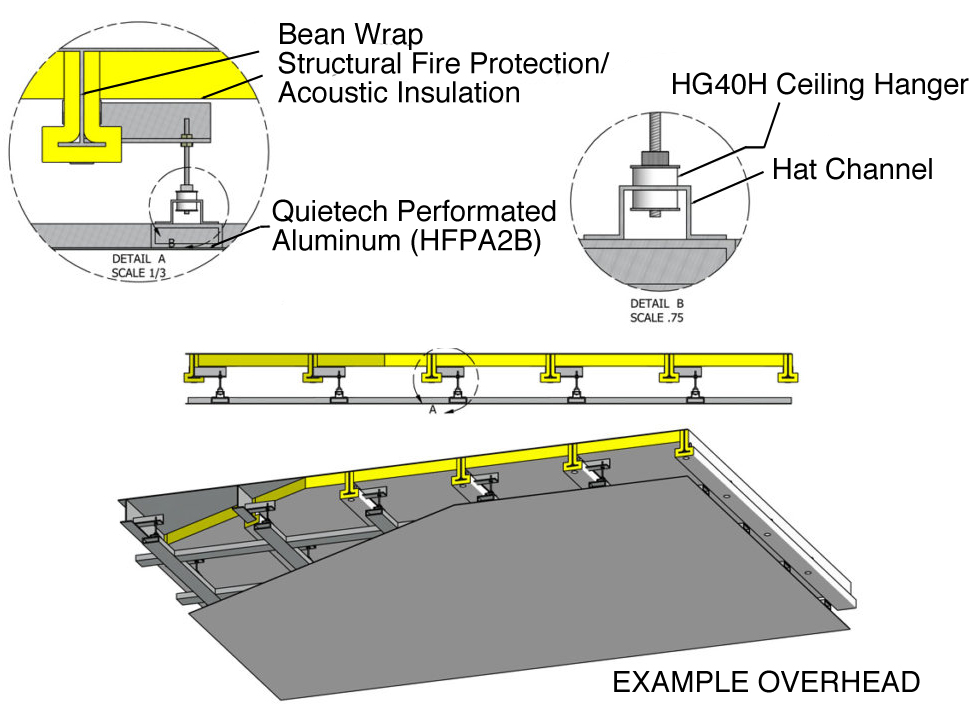

Insulating machinery spaces against noise and fire often requires a number of insulation materials to meet the vessel’s noise control requirements. The detail below shows insulation materials on the overhead that meet the fire rating and provide acoustic absorption. The mass required to block sound comes from the QuietClad damped aluminum sheet, which is also the finish material and provides the high level of finish required in yacht applications. For improved performance, the QuietClad is fastened to a hanging grid, which prevents the transmission of acoustically driven structureborne noise.

Soundown blankets are available in a range of materials, including Rockwool (mineral wool), Firemaster (Ceramic), Promoguard (silica), and Polyimide Foam, as well as a range of fiberglass, urethane foam, and non-woven materials. The materials can be fabricated with a number of mass layer and/or facing options to provide required transmission loss and aesthetic characteristics.

Soundown blankets are available in a range of materials, including Rockwool (mineral wool), Firemaster (Ceramic), Promoguard (silica), and Polyimide Foam, as well as a range of fiberglass, urethane foam, and non-woven materials. The materials can be fabricated with a number of mass layer and/or facing options to provide required transmission loss and aesthetic characteristics.

The level of finish required for a machinery space is typically based on the type of vessel. Yachts require a very high level of finish to match detailed equipment and polished chrome fittings. Work vessels have less requirement for aesthetics, but often benefit from the durability added by finishing the insulation with cladding materials.

Soundown offers both solid and perforated cladding options. QuietClad is a damped metal sheet that consists of two layers of sheet metal with a damper layer for acoustic performance. QuietClad is typically supplied in aluminum; however, steel and even polished stainless steel are available.

Soundown’s perforated aluminum is available in two standard hole patterns and powder coated white for a clean, durable finish. QuieTech perforated aluminum adds the acoustic and aesthetic advantages of our non-woven backing. This black backing provides a clean look behind the white finish and improves acoustic performance.