Drive Line Solutions

Drive lines can create a great deal of vibration, producing a range of disruptive sounds, from high-pitched shearing noises to deeper structural vibration. Soundown works with a fleet of different shaft solutions depending on your drive line configuration. Here are a few common solutions, but we encourage you to call us for a solution to fit your drive configuration.

Specifications TG (Torque Gearbox ) are semi elastic resilient mounts for free-standing gearboxes and/or close-coupled high-speed engines/gearboxes where the mountings have to absorb the torque reaction in combination with full propeller thrust.

TG (Torque Gearbox ) are semi elastic resilient mounts for free-standing gearboxes and/or close-coupled high-speed engines/gearboxes where the mountings have to absorb the torque reaction in combination with full propeller thrust.

Rubber Design shaft systems are ideal for heavy-duty shaft-related noise control, employing both active and passive control systems. Components include flexible couplings (a full range of flexible couplings designed to take high thrust and control the transmitted torque), thrust blocks (stand alone and stern-tube integrated), tail and intermediate shafts (manufactured in a range of materials from mild steel to high specification duplex steels), sterntubes, bracket bosses, bearings, stern seals, propellers, rudder stocks, and tubes.

These oil bath shafts are ideal if your axle is more than 4" in diameter.

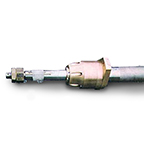

RD Flexible Shaft Couplings are designed to provide flexible connections between a propeller shaft and gear box, compensating for the motion of soft-mounted engines and reducing gear whine.

Specifications The Evolution Marine Shaft System (EMSS) is an oil bath shaft designed for smooth, quiet, low-maintenance propeller shaft installation. EMSS's integrated thrust bearing transfers the propeller thrust directly to the hull, which improves efficiency and allows for a softer mounting for smooth, quiet operation.

The Evolution Marine Shaft System (EMSS) is an oil bath shaft designed for smooth, quiet, low-maintenance propeller shaft installation. EMSS's integrated thrust bearing transfers the propeller thrust directly to the hull, which improves efficiency and allows for a softer mounting for smooth, quiet operation.

The Evolution Marine Shaft System (EMSS) is an oil bath shaft designed for smooth, quiet, low-maintenance propeller shaft installation. EMSS's integrated thrust bearing transfers the propeller thrust directly to the hull, which improves efficiency and allows for a softer mounting for smooth, quiet operation.

The Evolution Marine Shaft System (EMSS) is an oil bath shaft designed for smooth, quiet, low-maintenance propeller shaft installation. EMSS's integrated thrust bearing transfers the propeller thrust directly to the hull, which improves efficiency and allows for a softer mounting for smooth, quiet operation.