Isolation and Vibration Mounting Systems

Isolation and Vibration Mounting Systems

Noise from propulsion engines, marine diesel generators, and other mechanical sources travels by two paths: airborne and structureborne.

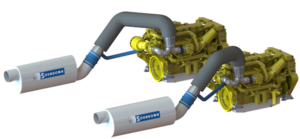

The structureborne path starts where the engine or other equipment is attached to the vessel. Vibration from the equipment is transmitted to the foundations where it propagates through the vessel and radiates into occupied areas – those vibrations turn into noise of different types and frequencies. Properly mounting engines, generators, and other equipment is the first step in reducing that noise aboard boats of all types.

With over 30 years of experience working with builders of pleasure boats, yachts, commercial vessels, combat craft, and specialty craft of all kinds, Soundown understands that every project is unique. Our technical staff will work with you to understand the requirements of your new build, refit, or repower, and develop isolation packages tailored to your project. This process takes into account performance requirements, the particulars of the vessel, budget, and logistics.

Soundown’s extensive selection includes isolators of all sizes and configurations. Most Soundown mounts use rubber elements, but spring and cable mounts are available as required. Our mounts are available in multiple configurations for ease of installation and service. Height adjusters are standard or optional on all mounts used under propulsion engines and large generators to allow precise balancing of loads and fast, easy realignment. Our Rubber Design conical mounts are even available with a split spindle, allowing installation that lifts the engine less than ¼”.

Soundown conducts static and dynamic reviews of the equipment to be mounted and reviews the supporting structure when appropriate. Our review process analyzes customer-supplied equipment data such as weight, center of gravity, and dimensions. These parameters are critical in selecting not only the type and stiffness of the mounts, but also where they should be positioned.

To understand the dynamics of the system, we also carry out a rigid body analysis. This enables us to design a solution specific to your vessel’s equipment and operating conditions. Through this analysis, we can calculate the displacement of mounted equipment during normal operation and under extreme conditions, which helps us select flexible connections for piping and other systems. One often overlooked element that’s important is the supporting structure to which the mount is fastened. If there is insufficient impedance, vibrational energy will transmit across the mount and into the structure. By working with your naval architects and experts, we can provide guidance on foundation requirements. Where a higher level of engineering support is necessary, our noise and vibration engineering partners at J&A Enterprises are available to review or even design effective support structure.

Proper isolation of equipment and systems is the foundation for a quiet, smooth-running vessel. Get Soundown involved as early as possible in the design phase of your next build, refit, or repower to achieve sound solutions.