|

|

Common noise sources and paths Main deck common spaces: Exterior Decks: Accommodation spaces: Pilot House & Sky Lounge: |

Yachts 110′ – 165′

Yachts this size may be highly customized, or they may be standard configurations. While there are standard treatments for common situations, which we’ll reveal below, many specific variations may have a greater or lesser effect on your particular vessel. Here are noise reduction treatments that can be deployed during or after construction, in order from the most likely to help to the treatments that are still helpful but less vital.

With 30 years of experience in high-end noise reduction, we’ve developed this list of recommendations. But remember no two vessels are really the same. To reach your most enjoyable boating experience, call us and set up a consultation.

Along with the vital measurements of a craft, consider how it’s most likely to be used. In-harbor boats have one set of sound requirements. Extended cruising may call for more attention to other sound issues – particularly, engine noise and vibration that can grow increasingly tiresome with prolonged exposure.

For Lloyd’s class boats in this size range, structural fire protection is also a consideration. A30, A60, A80, B and C are all available, but may require different materials to meet those specifications. The suggestions below don’t include structural fire protection details, but we can consult on variations for the below suggestions that will meet the most stringent requirements.

Treatment: Engine Isolation

Path: Structureborne

Source: Engine

Improved areas: Entire vessel. Engine room placement may be different in different vessels. So where engine noise manifests will vary depending on the boat’s architecture.

Problem: Yachts generally have larger engines than most vessels, which also leads to more noise, especially structureborne vibration.

- Isolation Mounts for the engine. These decouple the engine from the hull, isolating a significant portion of the vibration. While there are many options that can be considered, space constraints usually mean that engine and gear boxes are close coupled (see below for more advice on this coupling) and require a mount that can handle the force of the propeller thrust. The Rubber Design TT mounts (thrust & torque) are designed specifically for such applications. The TT’s unique design uses a series of rubber plates in shear to provide isolation when positively or negatively loaded. By combining size and rubber stiffness options, Soundown can select a mount that avoids excessive engine movement while providing ideal vibrational isolation.

- Mount and remote engine and gear package is a more systemic approach – when these are directly connected there is greater vibrational discord. If the elements can be separated,

- Drive shaft separation is another solution that can have a significant effect. Drive shaft noise usually expresses itself as a persistent whine – another frequency of noise that’s particularly uncomfortable for human ears. By making sure the drive shaft is not directly coupled to the engine. Think of a long pole with an end that’s tightly secured to a structure. As it tries to wiggle and move, it comes under signification stress. If, on the other hand, there’s a spring connecting it at the end, that spring will allow greater range of motion, with far less structural stress. The right flexible couplings for the drive shaft will help provide that “spring” effect. (you should also consider drive shaft baths, expanded on below).

- In a decoupled solution, your best path will be to put the engine on softer mounts with high deflection, while the gear box is on a stiffer rubber mount. Here’s an illustration of a remote mounted solution with a flexible shaft coupling.

- Note: Foundation design is a vital element in composing your engine mount system. What your mount is attaching to, and how far the engine will be from that surface, are crucial considerations in determining how flexible the rubber components need to be.

Treatment: Gear Noise Isolation

Path: Structurebourne, through the gear foundation

Source: Marine Reduction Gear

Improved areas: Salon, cabins, other interior spaces

Problem: The meshing of the gear teeth transmits vibrational energy into the structure of the vessel which radiates into all areas of the vessel. The most highly effected areas are directly adjacent to or above the engine room.

Solution: The most common misstep is to have a gear box that is hard-mounted to the foundation. The TG095 semielastic gear box mounts are specifically with an optimized blend of resiliency and stability. The ~1mm static deflection provides sufficient isolation to the higher frequency gear tones while providing a very stable installation of the gear box. This results in excellent acoustic performance while minimizing displacement of the shaft which can affect alignment and sealing systems.

TG095 semielastic gear mounts are custom to the gear box and foundations making installation easy for new builds or refits.

Path: Structurebourne, down the propeller shaft

Source: Marine Reduction Gear

Improved areas: Aft Cabins, Salon, Aft Deck

Problem: The meshing of the gear teeth transmits vibrational energy to the prop shaft and into the hull and radiates as structureborne noise in aft areas of the vessel.

Solutions: Rubber Design flexible shaft couplings combine a rubber bushings and urethane elements to provide a connection to the shaft that is soft radially to provide isolation, yet stiff axial for efficient transmission of thrust.

Treatment: Driveline Noise – Comprehensive

For vessels with extremely stringent noise and vibration levels the use of an oil bath shaft system should be a consideration. These systems include a sealed shaft tube that is filled with oil that allows the shaft to operate rotate more smoothly than water lubricated bearings. In addition to smooth operation in typical running scenarios oil bath shaft systems reduce stick slip and low speed squeal associated with DP operation or low shaft speed of diesel electric drives.

Treatment: Generator Mounting Systems

Path: Structurebourne

Source: Generator

Improved areas: Salon, cabins, deck

Problem: The operation of the generator transmits vibration into the hull which radiates as structurborne noise.

Solutions:

- The same principals apply to this heavy machinery as apply to engines. Isolating the vibration is the key. For larger systems, we may even put in double isolation mounting – a mounted platform, on which a second mounting system come between the machinery and that first platform. Often the machinery comes from the manufacturer with a set of mounts, which work but aren’t sufficient from an audio engineering perspective. To compensate, we install a bottom plate, with a mounting system under that. The performance and quality ranges widely for these resilient mounts.

- We consider not only the weight of the equipment when we specify these mount systems – the performance level and output relative to natural frequencies is also important. The specific vessel type and the shape of the machinery space are also important elements that go into the math which produces your ideal mounting system.

Treatment: Other Heavy Equipment Noise Mitigation

Path: Structurebourne

Source: Other heavy machinery

Improved areas: Salon and deck

Problem: The engine is properly mounted, the generator has been taken care of: But other elements in the machinery space can produce similar audio problems. Just like the engine, air conditioning, air trunks and pumps and sanitation units start to be a problem in the accommodation areas. That hum of an AC you’d expect in a cheap hotel room isn’t a welcome addition to a stateroom or salon. Hydraulics and winches can generate their own hums.

Solutions:

- Give Soundown a list of equipment and weights. Our engineers will want to know what is bolted onto a bulkhead or onto a less stiff / hardened structure. Non-flexible mounting is most often where the noise comes from. Location of equipment is also a big factor here – Soundown can consult on placement. At the pre-build stage, our consultation can save a lot of noise later. Bring us into the conversation earlier than you think you should to save money and noise down the line. Making sure the foundations match up with machinery mounts is crucial – even simply hitting the transoms correctly can result in a 2 or 3 decibel reduction in noise. Planning out your venting configuration can also have a significant impact.

Treatment: Exhaust Noise Mitigation

Path: Airbourne

Source: Exhaust from the engine or from generators

Improved areas: Decks, and shipwide to a lesser extent.

Problem: The engine is properly mounted, the generator has been taken care of: But other elements in the machinery space can produce similar audio problems. Just like the engine, air conditioning and pumps and sanitation units start to be a problem in the accommodation areas. That hum of an AC you’d expect in a cheap hotel room isn’t a welcome addition to a stateroom or salon. Hydraulics and winches can generate their own hums.

Solutions:

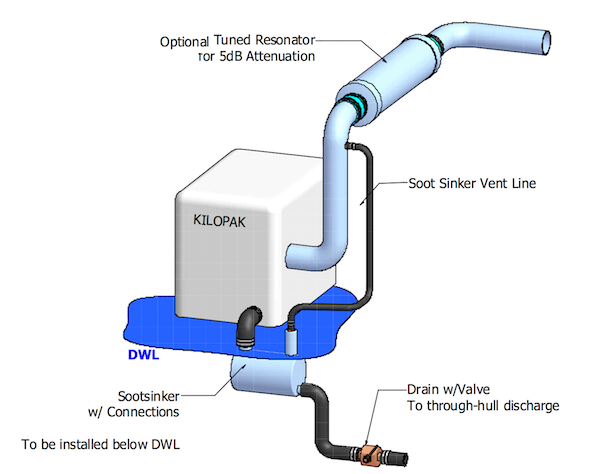

Custom exhaust systems can be attached to any vessel. This might mean an extensive system for a midship engine room or a ship that needs a stacked exhaust. It might mean an underwater exhaust. We have more information on exhaust configurations here.

Not all of our systems are patented, but we do often use patented technology to achieve ideal results for some boat styles. Soundown’s silencers are approved by Lloyd’s of London, meeting any required insurance standards, and have been certified by the international Maritime Organization (IMO), a certification that includes testing by Lloyd’s of the systems’ ability to consistently provide quality over the long term.

We also pay attention to implementation and the general aesthetics of the system, making sure that the level and tone of finish matches its surroundings.

We’re proud to produce some of the world’s quietest exhaust systems. Captains have told us they sometimes can’t even hear when their pumps are on. Generators also demand particular attention, as they are often used when your vessel isn’t at sea, with the added camouflage of wave noise. Generator silencers are available in any size, but we will often adjust a generator silencer to tone down a certain type or frequency of noise. Share your situation with us and we’ll maximize your quietness.

For example, a classic waterdrop silencer will take the water out of the steamy exhaust gas and release it below the water line to reduce both splashing and the weight of the exhaust travelling through the rest of the system. Using an active silencer with a tuned resonation limiter will cancel out the specific remaining wavelengths created by that process. An active silencer with tune resonation limiter works by canceling instead of creating noise, affecting the resonant frequency inside the exhaust. Every engine has a maximum allowable back pressure – we’ll do it without exceeding that pressure limit, without hurting your engine or voiding your warrantee. It’s a shame when everything looks like the ship in a glossy magazine ad, but doesn’t sound like it. The hum of exhaust can destroy the boating experience – but it’s entirely preventable.

Treatment: Engine Room / Machine Room Insulation

Path: Airborne

Source: Engine and other machinery in the engine space.

Improved areas: Salon, cabins, other interior spaces

Problem: The large engines found on yachts generate airborne noise in addition to structurborne. So does equipment like generators and air conditioners.

- Barrier composite insulation on the overhead and bulkheads. Barrier composites sandwich a layer of mass-loaded vinyl with acoustic foam. The foam absorbs noise while the mass-loaded layer reflects noise back into the engine room, protecting accommodation areas. Soundown’s IVF (insulated vinyl/foam) composite sheets are highly effective aboard most vessels and are easy to install in new builds or during refit.

Best bet: 2” 2lb for diesel engines, 2” 1lb for gas engines

- For hull sides or fuel tanks outboard of the engines we recommend Soundown’s IAF acoustic foams. IAF does not feature a barrier – the foam absorbs noise in the machinery space resulting less noise in the accommodations. It’s also effective at reducing airborne noise that often escapes through the ventilation system to other parts of the boat.

Best bet: 1”

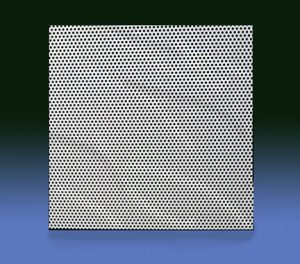

- For a high level of finish and additional noise reduction, Soundown QuieTech perforated aluminum sheets can be installed over insulation. The honeycombed cavities bounce the sound around, defracting and absorbing it.

- QuietClad damped aluminum is also available for vessels where a hard finished surface is standard. The QuietClad damped aluminum sheet provides both a clean white finish and excellent noise blocking properties, especially when used in conjunction with QuietStrips and acoustic fill. The more reflective surface often looks better, but has less effective sound damping qualities, reflecting some and even amplifying some wavelengths. The materials used are incombustible.

Best Bet: This depends on the speed you need from your craft. If keeping weight down is a top priority, thinner will be better – try .082” steel or aluminum. For ideal acoustic damping, heavier is better. Try .164” thickness and heavier fiberglass material.

- Floated bulk heads or even an entire floating interior can have a significant effect on noise reduction, essentially turning your floor into a layered sound absorber. Floated soles are hard surfaces raised or suspended with small fasteners, creating a thin absorbent layer or material or even air between the hull and the floor, ceiling or wall.

This approach is often used in staterooms, but it can also work in the engine space, if there is enough clearance to suspend a ceiling above the machinery. - Fasteners: When any insulation is being installed, it’s a best practice to use vinyl fasteners. These attach right through the frame to the wood or aluminum layer and creae an attachment point and gap for air flow to pass through.

Treatment: Cabin to Cabin Insulation

Path: Airborne

Source: Engine and other machinery in the engine space.

Improved areas: Cabins, other interior spaces

Problem: Even the largest vessels can present relatively tight living quarters, where sound may travel from stateroom to stateroom more than you’d like.

Solutions: Cabin to cabin is typically more important than cabin to passage insulation. Similarly, the galley, often home to noisy food preparation activities, may merit isolation from other areas. These can both be achieved with the following steps.

- Insulation: Barrier composite insulation on the overhead and bulkheads. Barrier composites sandwich a layer of mass-loaded vinyl with acoustic foam. The foam absorbs noise while the mass-loaded layer reflects noise back where it came from, protecting accommodation areas. Soundown’s IVF (insulated vinyl/foam) composite sheets are highly effective aboard most vessels and are easy to install in new builds or during refit.

Best bet: 2” 2lb barrier composite (1” 1lb if space is limited)

Product Specifications

- For vessels that spend a significant amount of time at sea, quilted fiberglass provides acoustic insulation that also meets relevant fire safety standards. The scrim and facing add cohesion to the fiberglass, which helps with fire resistance and makes the material easier to work with.

Best bet: quilted fiberglass composite insulation

Specifications

- Floating soles: As with engine and machine space noise mitigation, floating soles can help reduce noise transmission between interior spaces.

Treatment: Ventilation Noise

Path: Airborne

Source: Noise created by or travelling through the ventilation system

Improved areas: Salon, galley, cabins, other interior spaces, some on-deck spaces

Problem: Vents are designed to carry air – unfortunately, that often means they also carry or even amplify sound.

Solutions:

- Isolating fans: Especially relevant when large fans are involved, this is a remedy that’s best to explore before early in the build process. If you take many of the above steps to reduce engine noise, then end up with significant fan noise, it can still leave you with a loud vessel. Specially isolated fans can reduce both vibration and air-based noise, and selection of proper equipment can make a considerable difference.

- Duct treatments: Duct noise can be affected by strategically placed filters and insulation in particular problem areas, such as back corners of many salons, where low vents are often placed without consideration of acoustics. Adding turns or loops to a ventilation system will also reduce sound. To reduce noise transmission, you want to make sure there is no direct line of sight between a ventilation source and a vent.